Case study: Finding Crop Stress Before it Robs the (Yield) Bank

In an earlier article, we talked about how remote sensing can be used to make field scouting more efficient by allowing early detection, quantification of the extent and location of stresses, and tracking changes in areas of interest over time. You can read more about it here. This article will give you some real-world examples of how an independent crop consulting company, CropQuest, has worked alongside the team at FluroSat to integrate remote sensing into their field scoutings to save time and money.

Lessons learned last season: detecting and tracking crop damage over time

CropQuest used FluroSense for the first time in the 2019 growing season. It allowed the team to get comfortable with the tools and develop their scouting program around the tech-driven products offered by FluroSense. One of the biggest learnings was understanding crop stress over time, and deciding on the optimal time to act on it. For some types of stress, the actions are not possible in the season, but instead, they take place after harvest or at planting.

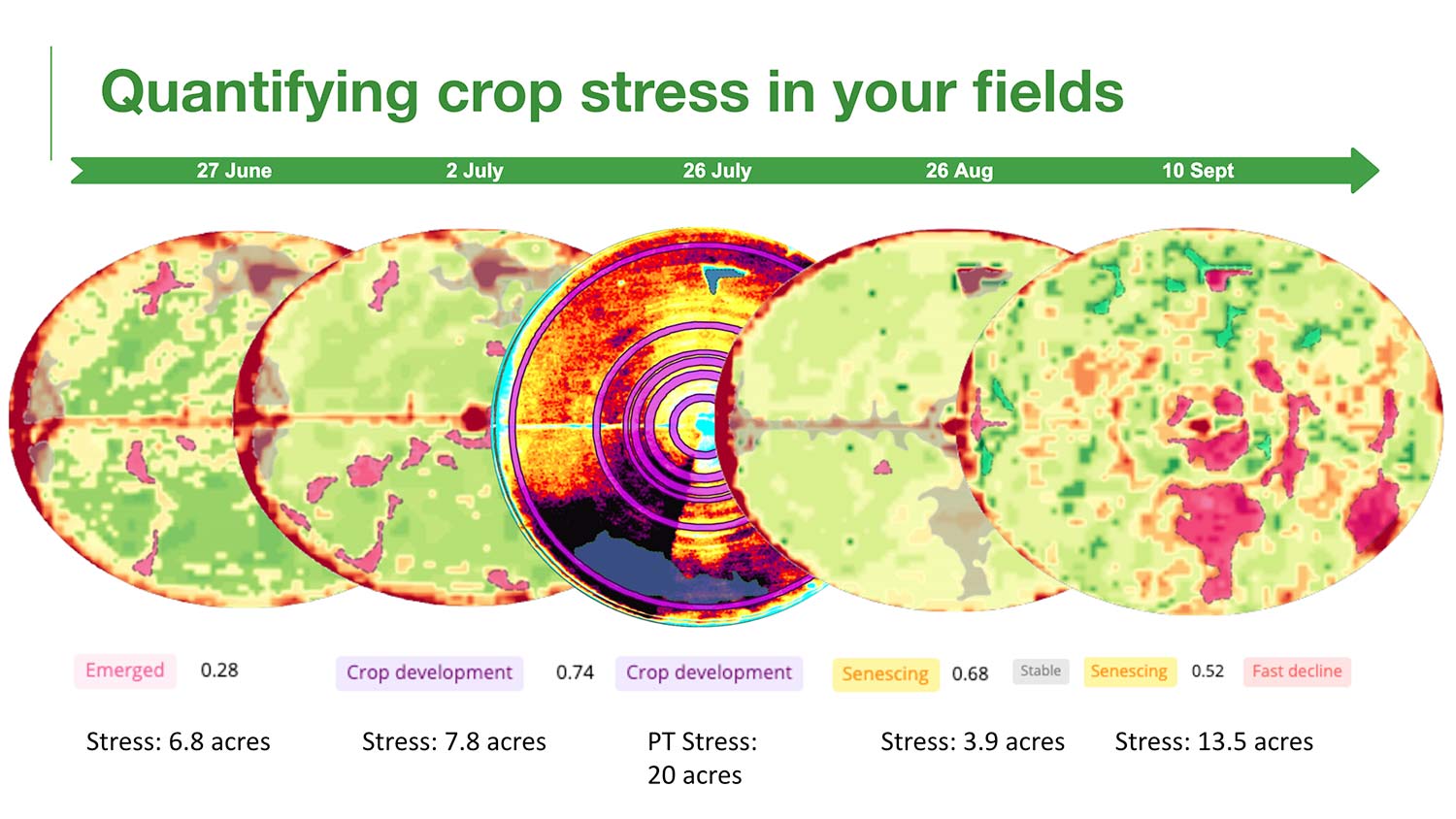

Here is an example of the field from last season (2019) where remote sensing imagery showed growing stress during the course of the season. The early stress in the Northern part of the field was scouted and identified to be ponding as a result of a lot of rain. After ponding has prevented the crop emergence, the area remained bare (no vegetation) and showed high reflectance in the thermal band and low in NDVI.

Other areas in the field suggested for scouting and outlined with geo-referenced polygons by FluroSense smart crop stress detection algorithms were regularly scouted by agronomists to see if poor soil conditions in parts of this field would make crop susceptible to disease or pest attacks.

Gibson states that most of the damage was able to be reversed when they identified it. This can be seen in the reduction of stressed areas from 7.8 acres in July to 3.9 acres in August.

For some fields where the Crop Stress monitoring system wasn’t commissioned in the last growing season, and the stress wasn’t prevented in time it caused the “dip” in the yield visible at a later growth stage, as seen in the above drone image taken by John Gibson.

As a result of these post-season findings in 2019 CropQuest team decided to grow its program with FluroSense in 2020 and is now securing the crop condition of many more growers using FluroSense crop stress alerts.

Summary

Finding Crop Stress Before it Robs the (Yield) Bank:

- Early crop stress detection is powered by specialised cameras on satellites helps detect crop stress symptoms earlier than with naked eyes.

- With FluroSense regular reports and stress detection alerts, crop scouts don’t need to worry about checking each field every time they visit a grower.

- Evaluate the risk of having the stress in all of your fields, and see how the program pays off. Putting the reports on just some fields might not solve the issue.

- You can access a FREE crop stress report for the current or the last year crop to know how much crop stress really costed you, and whether it was worth monitoring in season.

For more examples of how crop stress detection pays, please, refer to this article. If you would like to get access to advanced crop scouting tools and integrate them into your crop protection program or a precision ag offering to your growers, just like CropQuest did, don’t hesitate to contact us. Get your FREE crop stress report today!